إن اختبار كل كاميرات الدوائر التلفزيونية المغلقة قبل الشحن ليس مجرد ممارسة تجارية جيدة، بل هو أمر ضروري لمنع الإرجاع المكلف والحفاظ على ثقة العملاء. بصفتي شخصًا يعمل في صناعة كاميرات المراقبة منذ سنوات، فقد رأيت عن كثب كيف يمكن للاختبار المناسب قبل الشحن أن يحافظ على سمعة الشركة أو يحطمها. يتضمن الاختبار الفعال لكاميرات الدوائر التلفزيونية المغلقة عملية منهجية من 5 مراحل تشمل الاختبار الوظيفي، واختبارات الإجهاد البيئي، والتحقق من التكامل، وتوثيق الجودة، وفحص التغليف النهائي. يقلل هذا النهج الشامل من الأعطال الميدانية بنسبة تصل إلى 85% و تضمن الكاميرات أداءً موثوقاً في ظروف العالم الحقيقي. دعني أشرح لك بالضبط كيف نضمن أن كل كاميرا تغادر منشأتنا تلبي أعلى المعايير. لقد ساعدنا هذا النهج المنهجي في الحفاظ على معدل إرجاع أقل من 2% مع بناء علاقات دائمة مع عملائنا. تجمع منهجية الاختبار لدينا بين الصناعة أفضل الممارسات مع سيناريوهات العالم الحقيقي لضمان أداء كل كاميرا كما وعدت بالضبط.

لماذا يعد اختبار ما قبل الشحن أمرًا بالغ الأهمية لجودة كاميرات الدوائر التلفزيونية المغلقة؟

تبدأ منهجية الاختبار الصارمة التي نتبعها لحظة وصول الكاميرات من الإنتاج الخط. لقد طورت نهجًا منهجيًا يفحص كل مكون قبل أن تغادر أي وحدة منشأتنا.

أولاً، نقوم بإجراء فحوصات بصرية لتحديد العيوب الواضحة - العدسات المخدوشة أو الوصلات المفكوكة أو تلف الغلاف. يكتشف هذا الفحص الأولي حوالي 8% من المشكلات المحتملة على الفور. بعد ذلك يأتي اختبار التشغيل، حيث نتحقق من الوظائف الأساسية، بما في ذلك تسلسل الإقلاع ومؤشرات LED والاتصال الأولي بالشبكة.

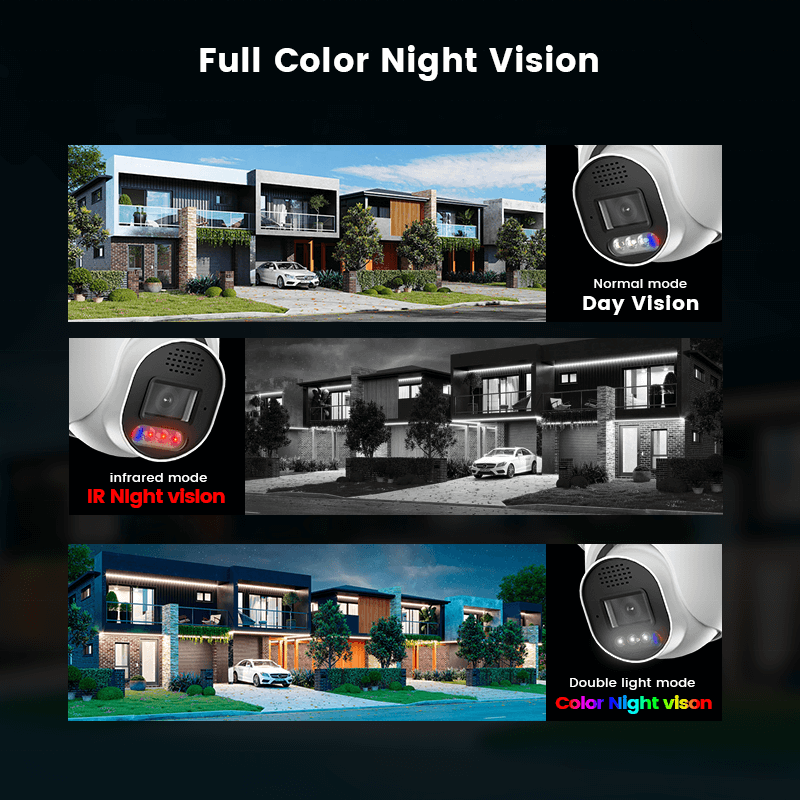

يتضمن جوهر عمليتنا إجراء اختبارات وظيفية عبر سيناريوهات متعددة. نقوم بتقييم جودة الصورة في ظل ظروف الإضاءة المختلفة، واختبار حساسية اكتشاف الحركة، والتحقق من أداء الأشعة تحت الحمراء في الظلام الدامس. يجب أن تجتاز كل كاميرا مواصفات صارمة لوضوح الدقة ودقة الألوان والأداء في الإضاءة المنخفضة.

| فئة الاختبار | المدة | معدل النجاح |

|---|---|---|

| الفحص البصري | 5 دقائق | 92% |

| اختبار التشغيل | 10 دقائق | 96% |

| الاختبار الوظيفي | 2-4 ساعات | 89% |

يحاكي اختبار الضغط البيئي ظروف العالم الحقيقي، بما في ذلك تقلبات درجات الحرارة وتغيرات الرطوبة. كما نقوم أيضًا بإجراء تحديثات البرامج الثابتة واختبار التكوين لضمان سلاسة التكامل مع أنظمة الأمان الحالية. في جير-تك، أدى هذا النهج الشامل إلى خفض معدلات الإرجاع لدينا بنسبة 67% مقارنة بمعايير الصناعة. إذا كنت بحاجة إلى متطلبات اختبار محددة لمشروعك، فإن فريقنا في اتصل بنا تخصيص البروتوكولات لتتناسب مع احتياجات النشر الخاصة بك.

كيف يبدو سير عمل الاختبار خطوة بخطوة؟

بناءً على أساس أهمية اختبار ما قبل الشحن، دعني أطلعك على سير العمل الفعلي خطوة بخطوة الذي يحول مراقبة الجودة من مفهوم إلى واقع.

تبدأ عمليتنا بأخذ عينات على دفعات - نقوم بسحب 2-3 كاميرات من كل عملية إنتاج بدلاً من قبول عينات مختارة من الشركة المصنعة. هذا يمنع مشكلة "العينة الذهبية" الكلاسيكية حيث يتم اختبار أفضل الوحدات فقط. لقد رأيت الكثير من الشركات تتعرض للحرق من خلال هذا النهج، لذلك نحن نصر على الاختيار العشوائي.

يتبع سير العمل جدول زمني صارم مدته 72 ساعة. يتضمن اليوم الأول فحوصات أولية واختبار الاحتراق في ظروف درجة حرارة مضبوطة. نقوم بتشغيل الكاميرات بشكل متواصل لمدة 24 ساعة لتحديد مكونات الأعطال المبكرة - فكر في الأمر على أنه تقادم متسارع يكشف عن المشاكل التي قد تظهر بعد أشهر من الاستخدام الميداني.

| مرحلة الاختبار | المدة | مجالات التركيز الرئيسية |

|---|---|---|

| اختبار الاحتراق | 24 ساعة | ثبات المكونات، وتبديد الحرارة |

| التحقق الوظيفي | 12 ساعة | جودة الصورة واتصال الشبكة |

| الإجهاد البيئي | 24 ساعة | تدوير درجة الحرارة، والتعرض للرطوبة |

| اختبار التكامل | 12 ساعة | توافق البرامج وتحديثات البرامج الثابتة |

يركّز اليوم الثاني على اختبار الإجهاد البيئي - دورات درجة الحرارة من -10 درجات مئوية إلى 50 درجة مئوية، وتغيرات الرطوبة ومقاومة الاهتزازات. يتضمن اليوم الثالث اختبار التكامل مع مختلف تكوينات الشبكة ومنصات البرامج. في جير-تك، ساعدنا هذا النهج المنهجي في الحفاظ على معدل نجاح النشر الأول 97%. لمتطلبات الاختبار المخصصة الخاصة ببيئة التثبيت الخاصة بك, اتصل بفريقنا الفني لمناقشة بروتوكولات التحقق المصممة خصيصًا.

كيف نقيس مقاييس مراقبة الجودة الأساسية؟

إذا تجاوزنا سير عملنا المنهجي، فإن السحر الحقيقي يحدث في كيفية قياس الأداء من خلال بروتوكولات القياس الدقيقة. فالأرقام لا تكذب، وهي بالتأكيد لا تغطّي عيوب الكاميرا التي قد تفلت من الفحص البصري.

يركز نهج القياس الذي نتبعه على خمسة مقاييس مهمة ترتبط مباشرةً بالأداء الميداني. يتجاوز اختبار دقة الفيديو العد البسيط للبكسل - فنحن نستخدم مخططات اختبار ISO 12233 لقياس أزواج الخطوط الفعلية لكل مليمتر، مما يكشف عن مشكلات جودة العدسة التي تخفيها أوراق المواصفات في كثير من الأحيان. لقد رأيت كاميرات تدّعي دقة 4K التي بالكاد تحقق وضوح 2K في ظروف الاختبار الحقيقية.

تحظى دقة الكشف عن الحركة باهتمام خاص لأن الإنذارات الكاذبة تصيب فرق الأمن بالجنون. نحن نختبر باستخدام أجسام تتراوح بين الحيوانات الصغيرة والمركبات بسرعات مختلفة، مع الحفاظ على عتبة دقة 95%. يتضمن اختبار اتصال الشبكة اختبارات إجهاد النطاق الترددي ومراقبة فقدان الحزمة في ظل ظروف تحميل مختلفة.

| مقياس الجودة | عتبة النجاح | طريقة الاختبار |

|---|---|---|

| دقة الفيديو | 90% من الخطوط المصنفة | مخطط اختبار ISO 12233 ISO 12233 |

| كشف الحركة | دقة 95% | تتبع الأجسام متعدد السرعات |

| الرؤية الليلية النطاق | 85% من مسافة المواصفات | اختبار الظلام المتحكم به |

| استقرار الشبكة | <0.1% فقدان الحزمة <0.1% | اختبار الإجهاد لمدة 48 ساعة |

يحاكي اختبار استعادة الطاقة الانقطاع الحقيقي للطاقة عن طريق قطع الطاقة في منتصف التشغيل وقياس وقت الاستعادة. في جير-تك، تضمن هذه المعايير القابلة للقياس الكمي استيفاء كل كاميرا للمواصفات الموثقة قبل الشحن. للحصول على المتطلبات القياسية التفصيلية الخاصة بمشروعك، يمكن لفريقنا الهندسي في اتصل بنا يمكن أن توفر بروتوكولات اختبار مخصصة.

ما هي اختبارات البيئة والمتانة التي نجريها؟

بعد وضع مقاييس دقيقة للجودة، فإن تواجه الكاميرات في نهاية المطاف ظروف اختبار البقاء على قيد الحياة التي من شأنها أن تجعل الهاتف الذكي يبكي. تعمل حجرة الاختبار البيئية الخاصة بنا على تسريع الشيخوخة في العالم الحقيقي، حيث تحشر سنوات من التعرض في جلسات مكثفة مدتها 72 ساعة.

يشكل تدوير درجات الحرارة العمود الفقري لاختبارات المتانة التي نجريها. نحن نُخضع الكاميرات لانتقالات سريعة من -20 درجة مئوية تحت الصفر إلى +60 درجة مئوية، لمحاكاة كل شيء من شتاء القطب الشمالي إلى صيف الصحراء. يكشف هذا الإجهاد الحراري عن نقاط ضعف المكونات التي لا تظهر إلا بعد أشهر من النشر الميداني. لقد رأيت كاميرات يفترض أنها قوية تفشل الكاميرات بشكل مذهل في درجات الحرارة القصوى لأن الشركات المصنعة تخطي هذه المرحلة الحاسمة.

يعمل اختبار الرطوبة على دفع مستويات الرطوبة إلى 95% أثناء مراقبة التكثيف الداخلي وأعطال مانع التسرب. لا شيء يفسد نظام الأمان أسرع من تسرب المياه، لذلك نقوم باختبار تعذيب كل حشية ومفصل مبيت. يحاكي اختبار الاهتزازات التركيب على أعمدة المرور وهياكل المباني والمواقع التي تهب فيها الرياح باستخدام ترددات تتراوح من 5 هرتز إلى 2000 هرتز.

| الاختبار البيئي | نطاق الحالة | المدة |

|---|---|---|

| تدوير درجة الحرارة | -20 درجة مئوية إلى +60 درجة مئوية | 48 ساعة |

| التعرض للرطوبة | حتى 95% RH حتى 95% RH | 24 ساعة |

| اختبار الاهتزازات | 5 هرتز إلى 2000 هرتز | 12 ساعة |

| التعرض للأشعة فوق البنفسجية | 40 وات/م² شدة 40 وات/م² | 168 ساعة |

يمنع اختبار التعرّض للأشعة فوق البنفسجية التدهور البلاستيكي المحرج الذي يحوّل الكاميرات الاحترافية إلى كاميرات مهترئة. يحاكي اختبار السقوط حوادث التركيب ومحاولات التخريب - يجب أن تحافظ الكاميرات على محاذاة التركيز البؤري حتى بعد الصدمات المعتدلة. في جير-تك، تضمن هذه البروتوكولات الصارمة نجاة كاميراتنا من البيئات القاسية التي تتغلب على المنتجات الأقل. لمتطلبات الاختبار الخاصة بالبيئة للظروف القاسية, اتصل بفريقنا الفني لمناقشة إجراءات التحقق المتخصصة.

كيف نتحقق من التكامل وتوافق النظام؟

بعد إجراء اختباراتنا البيئية الصارمة تواجه الكاميرات تحديهم الأخير - إثبات قدرتها على الاندماج بسلاسة مع البنية التحتية الأمنية الحالية. وغالباً ما تكشف هذه المرحلة عن كوابيس التوافق التي يغفلها الاختبار المستقل تماماً.

يشبه مختبر التكامل لدينا نظام الأمان متحف يضم العشرات من طرازات NVR/DVR ومنصات VMS. نحن نختبر كل الكاميرا ضد الأنظمة الشائعةبما في ذلك Milestone و Blue Iris والبرامج الخاصة بالشركة المصنعة لضمان التوافق الكامل للميزات. لا شيء يحبط المثبِّتين أكثر من اكتشاف تحليلات الكاميرا المتقدمة لا تعمل مع نظام إدارة الفيديو الافتراضي المفضل لديهم.

يبدأ اختبار تكامل الشبكة بالتحقق من توصيل طاقة PoE عبر مختلف الشركات المصنعة للمفاتيح - بعض المفاتيح توفر طاقة أنظف من غيرها، مما يؤثر على استقرار الكاميرا. نقوم بمحاكاة ازدحام الشبكة عن طريق إغراق شبكات الاختبار بحركة المرور أثناء مراقبة فقدان الحزمة أو انقطاع الاتصال.

| فئة اختبار التكامل | الأنظمة التي تم اختبارها | نقاط التفتيش الحرجة |

|---|---|---|

| التوافق مع NVR | 12 علامة تجارية كبرى | وصول كامل للميزات وثبات التسجيل |

| تكامل VMS | 8 منصات برمجيات | التحليلات، والتحكم في PTZ، ومشغلات الإنذار |

| أداء الشبكة | أنواع مختلفة من المفاتيح | توصيل PoE، وتحسين عرض النطاق الترددي |

| التحقق من البروتوكول | ONVIF، RTSP، ملكية خاصة | استقرار الدفق، استجابة الأوامر |

اختبار البروتوكول تضمن الكاميرات التواصل بشكل صحيح باستخدام معايير ONVIF وبروتوكولات الملكية. يتحقق اختبار مزامنة الكاميرات المتعددة من إمكانية تشغيل وحدات متعددة في وقت واحد دون تعارض. في جير-تك، فإن اختبار التوافق الشامل هذا يزيل مفاجآت التثبيت ويضمن استفادة الكاميرات من استثمارات البنية التحتية الحالية بفعالية. لمتطلبات التكامل المحددة مع أنظمتك الحالية, اتصل بأخصائيي التوافق لدينا للتحقق من التكامل السلس قبل النشر.

ما هي إجراءات التوثيق والشحن التي تضمن الجودة؟

بعد الانتهاء من اختبار التكامل، تتلقى كاميراتنا جواز سفرها النهائي للحصول على وثائق مفصلة للجودة تتبع كل وحدة طوال دورة حياتها بالكامل. هذه الأعمال الورقية ليست مجرد تكاليف بيروقراطية زائدة؛ بل هي الفرق بين الحل السريع للمشاكل وأسابيع من المشاكل التي تستغرق أسابيع من استكشاف الأخطاء وإصلاحها.

كل تتلقى الكاميرا رقمًا تسلسليًا فريدًا يتصل إلى أرشيف رقمي يحتوي على نتائج اختبار كاملة، وتفاصيل دفعة الإنتاج، وإصدارات البرامج الثابتة، وتوقيعات المفتشين. تتجاوز تقارير مراقبة الجودة الخاصة بنا مجرد علامات النجاح/الفشل، حيث يتلقى العملاء بيانات قياس فعلية توضح بدقة أداء كاميراتهم أثناء الاختبار. هذه المعلومات التفصيلية لا تقدر بثمن لتخطيط النظام واستكشاف الأخطاء وإصلاحها في المستقبل.

إجراءات التعبئة والتغليف حماية الكاميرات من تلف الشحن من خلال مواد مضادة للكهرباء الساكنة وإدخالات رغوية مخصصة وأكياس عازلة للرطوبة. تتضمن كل عبوة تعليمات المناولة و أدلة إعداد لتجنب أخطاء التثبيت التي قد تضر بالأداء.

| نوع التوثيق | المعلومات المتضمنة | مزايا العميل |

|---|---|---|

| تقرير الاختبار | القياسات الفعلية وبيانات الأداء | تخطيط النظام واستكشاف الأخطاء وإصلاحها |

| سجل التتبع | معلومات الدفعة، توقيعات المفتش | دعم الضمان، وتتبع الجودة |

| شهادة ضمان الجودة | التحقق من طرف ثالث | متطلبات الامتثال |

| وثائق الإعداد | أدلة التثبيت، المواصفات | تقليل أخطاء التثبيت |

توفر شهادات ضمان الجودة تحققاً من طرف ثالث يساعد العملاء في كثير من الأحيان على تلبية متطلبات الامتثال الحكومية أو متطلبات الشركات. في جير-تك، يدعم مسار التوثيق هذا مطالبات الضمان، ويتيح الدعم الفني الفعال، ويوضح التزامنا بمعايير الجودة. للحصول على متطلبات التوثيق المخصصة لاحتياجات الامتثال الخاصة بك, اتصل بفريق ضمان الجودة لدينا لمناقشة خيارات إعداد التقارير المخصصة.

الاستنتاجات

اختبار كل كاميرا CCTV قبل الشحن يمثل التزامنا بتقديم حلول أمنية موثوقة. وقد مكننا هذا النهج المنهجي من بناء علاقات دائمة مع العملاء مع الحفاظ على معايير الجودة الرائدة في الصناعة التي تحمي سمعتنا وسمعة عملائنا على حد سواء الأمن الاستثمارات. من خلال اتباع هذه الإجراءات التي أثبتت جدواها، يمكننا أن نقف بثقة وراء كل منتج نقوم بشحنه.