Choosing an AHD camera supplier can make or break your security project. With countless manufacturers claiming superior quality and competitive prices, how do you separate genuine partners from unreliable vendors? The wrong choice leads to system failures, costly delays, and frustrated clients. The security camera market is projected to reach $95-100 billion by 2030, with AHD technology maintaining a significant market share due to cost-effective HD upgrades. However, this growth attracts both legitimate manufacturers and questionable suppliers looking for quick profits. This comprehensive guide reveals the exact criteria security professionals use to evaluate AHD camera suppliers. You’ll learn how to verify supplier credibility, assess technical capabilities, and avoid costly mistakes that could jeopardize your project’s success.

What Technical Specifications Should You Prioritize in AHD Camera Suppliers?

Understanding technical specifications isn’t just about reading datasheets—it’s about distinguishing between suppliers who truly understand AHD technology and those simply reselling generic products. I’ve learned that the most critical mistake buyers make is accepting vague performance claims without demanding concrete evidence.

Resolution capabilities form your foundation, but don’t assume all suppliers interpret these specifications equally. While 2MP suffices for basic monitoring, critical applications demand 4-5MP performance with actual pixel density measurements, not just marketing numbers. For high-security installations requiring 8MP capabilities, verify that suppliers can demonstrate real-world performance rather than theoretical maximums.

| Application TypeMinimum ResolutionRecommended Features | ||

|---|---|---|

| Basic Perimeter | 2MP (1080p) | 30m IR range, IP66 |

| Critical Areas | 4-5MP | 0.01 lux rating, IK10 |

| High-Security Zones | 8MP (4K) | 80m IR, -30°C to +60°C |

Low-light performance separates professional suppliers from amateur operations. Demand actual lux ratings (0.01 lux or better) with supporting test footage captured in real conditions, not laboratory environments. Similarly, IR illumination distances should reflect outdoor performance, accounting for environmental factors that laboratory measurements ignore.

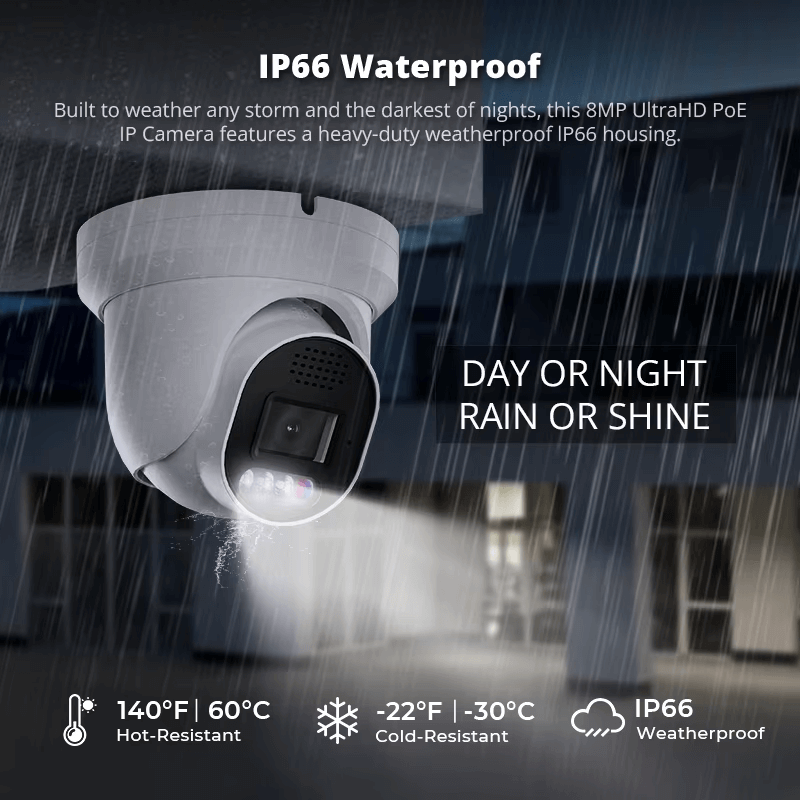

Weatherproofing specifications reveal supplier quality standards. IP66/67 ratings represent minimum professional standards, while IK10 vandal resistance matters for accessible locations. Operating temperature ranges must match your specific environment—standard -20°C to +50°C specifications work for most applications, but industrial environments may require extended ranges. Reliable suppliers from established manufacturers provide comprehensive documentation supporting these claims, including detailed installation guides and environmental testing results rather than generic marketing materials.

How Important Is Product Range and System Compatibility?

Product range complexity becomes evident once you move beyond basic camera specifications into real-world deployment scenarios. I’ve seen countless projects derailed because buyers selected suppliers with limited portfolios, forcing them to juggle multiple vendors and incompatible systems. The hidden costs of managing diverse supplier relationships often exceed initial price savings.

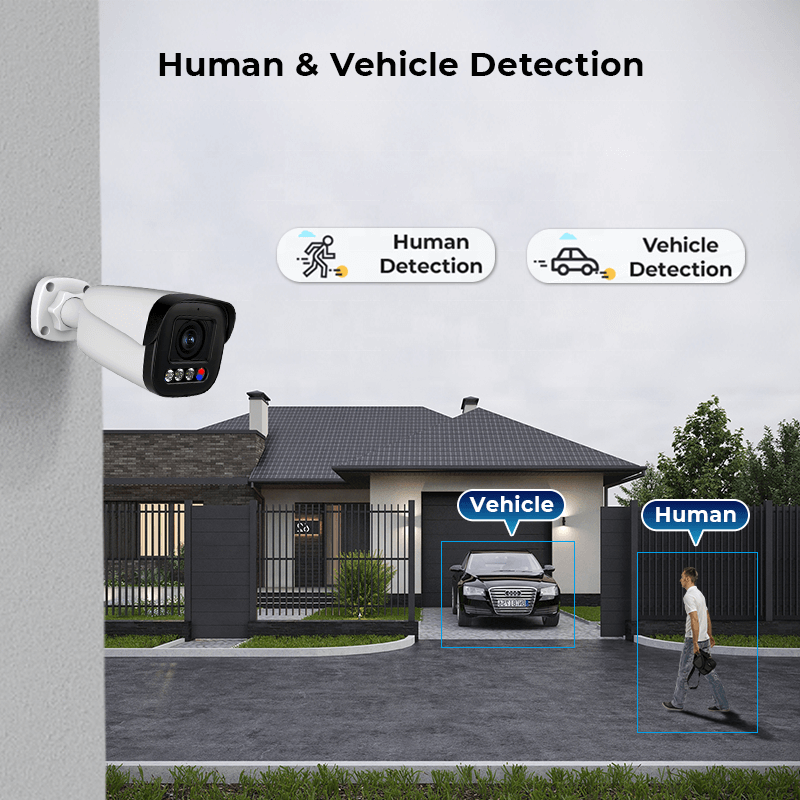

Professional installations demand specific camera formats for different applications. Bullet cameras excel at perimeter monitoring with their focused directional coverage, while dome cameras provide discreet indoor surveillance with vandal-resistant housings. Turret cameras offer mounting flexibility for challenging locations, and PTZ units enable active tracking capabilities. A complete supplier portfolio should include matching DVRs, XVRs, and essential accessories to avoid compatibility issues.

| Camera TypePrimary ApplicationKey Advantages | ||

|---|---|---|

| Bullet | Perimeter monitoring | Long-range IR, weatherproof |

| Dome | Indoor areas | Vandal-resistant, discreet |

| Turret | Versatile mounting | Easy adjustment, compact |

| PTZ | Active surveillance | Remote control, zoom capability |

System compatibility extends far beyond camera-to-recorder connections. Modern AHD installations increasingly require integration with VMS platforms, access control systems, and centralized monitoring stations. Verify that your supplier’s hybrid DVR/XVR units support multiple analog formats (AHD, TVI, CVI, CVBS) plus IP camera inputs for future expansion flexibility. This proves particularly crucial for retrofit projects involving mixed camera technologies.

Storage compatibility represents another critical consideration often overlooked until deployment. AHD cameras generate substantial data volumes, especially at higher resolutions, requiring suppliers who provide clear guidance on compression efficiency and storage requirements. Established manufacturers often partner with storage providers to offer pre-tested, optimized solutions that eliminate guesswork from capacity planning. For technical support and detailed compatibility information, professional consultation can prevent costly integration challenges down the road.

What Quality Assurance Measures Separate Professional Suppliers?

Quality assurance separates genuine manufacturers from operations that merely assemble components without rigorous oversight. I’ve encountered too many suppliers who claim “strict quality control” but can’t produce documented evidence of their processes. The difference between professional-grade equipment and consumer-level products often comes down to systematic testing and verification procedures.

ISO 9001 certification provides baseline assurance, but experienced buyers examine actual QC processes rather than relying on certificates alone. Request detailed documentation covering component qualification, incoming inspection procedures, and production testing protocols. Professional suppliers readily share this information, while assembly operations typically provide vague responses.

| Quality Stage | Testing Requirements | Professional Standards |

|---|---|---|

| Component Qualification | Sensor/chipset verification | Performance specifications met |

| Incoming Inspection | Parts verification before assembly | Prevents substandard components |

| Production Testing | Electrical, optical, environmental | Multi-stage verification process |

| Burn-in Testing | Elevated stress conditions | Identifies early failure modes |

Burn-in testing represents a critical differentiator that many suppliers skip due to cost and time requirements. This process operates finished cameras under elevated temperature and stress conditions to identify potential early failures. Quality suppliers invest in dedicated burn-in facilities despite the expense because field failure rates drop significantly.

Third-party verification adds credibility to quality claims. Professional suppliers from established manufacturers welcome independent inspection services that verify production processes and test random samples. If you need assistance evaluating supplier quality credentials, professional consultation can help identify which certifications and processes truly matter for your specific application requirements.

How Do You Assess Production Capacity and Delivery Reliability?

Production capacity evaluation goes far beyond asking suppliers for monthly output numbers—I’ve learned that many inflate these figures without considering actual bottlenecks in their manufacturing processes. The reality is that stated capacity and achievable delivery performance often differ dramatically, particularly during peak demand periods or component shortages.

SMT (Surface Mount Technology) line capacity represents the true manufacturing bottleneck for most AHD camera suppliers. Professional manufacturers operate multiple SMT lines to ensure redundancy and handle demand spikes, while smaller operations rely on single lines that create vulnerability. Ask suppliers about their SMT line configuration and backup capabilities rather than accepting generic capacity claims.

| Supplier Size | Monthly Capacity | SMT Lines | Flexibility Rating |

|---|---|---|---|

| Small Operations | 500-2,000 units | 1-2 lines | Limited |

| Mid-tier Manufacturers | 5,000-20,000 units | 3-6 lines | Moderate |

| Large Manufacturers | 50,000+ units | 10+ lines | High |

Assembly line configuration affects both capacity and flexibility in ways that impact your project timeline. Dedicated lines offer higher efficiency for specific camera types but lack adaptability, while configurable lines accommodate changing product mixes at the cost of some efficiency. Suppliers serving diverse markets typically maintain flexible assembly capabilities.

Raw material inventory management reveals supply chain sophistication that directly impacts delivery reliability. Professional suppliers maintain a strategic inventory of semiconductors and specialized sensors subject to allocation or extended lead times. This buffer inventory requires working capital investment but protects against supply disruptions that could delay your project. Established manufacturers often provide transparent capacity reporting and delivery commitments backed by proven track records. For detailed capacity evaluation assistance, professional consultation can help verify supplier claims and identify potential delivery risks before they impact your timeline.

Why Does Pricing Structure Matter Beyond Unit Cost?

Pricing transparency exposes more about supplier business practices than many buyers realize—I’ve encountered suppliers who use complex pricing structures to disguise quality compromises or financial instability. The cheapest unit price rarely translates to the lowest total project cost, particularly after factoring in failure rates, warranty support, and hidden fees.

Total cost of ownership calculations reveal the true financial impact of supplier selection. A supplier offering 20% lower unit pricing but experiencing 5x higher failure rates actually costs significantly more through replacement units, labor expenses, and customer satisfaction issues. Professional suppliers provide detailed pricing breakdowns, including volume tiers, shipping terms, and payment conditions without hidden surprises.

| Cost Factor | Budget Impact | Professional Standard |

|---|---|---|

| Unit Price | Initial purchase cost | Volume tier pricing |

| Failure Rate | Replacement/labor costs | 2% or lower annually |

| Warranty Terms | Risk allocation | 2-3 years standard |

| RMA Process | Operational overhead | Clear procedures/timelines |

Warranty terms significantly affect ongoing costs and risk allocation beyond the initial purchase. Standard warranty periods for professional equipment range from 2-3 years, with volume customers often receiving extended coverage. Understand what warranty coverage includes, response times for claims, and whether advance replacement options minimize downtime.

RMA (Return Merchandise Authorization) processes impact operational costs through administrative overhead and system downtime. Efficient RMA procedures with reasonable processing times and fair freight allocation separate professional suppliers from operations that treat warranty service as profit centers. Established manufacturers typically offer streamlined warranty processes that minimize your operational disruption. For assistance in evaluating the total cost of ownership across different suppliers, professional consultation can help identify hidden costs and ensure accurate project budgeting.

What After-Sales Support Standards Should You Expect?

After-sales support quality often reveals more about supplier reliability than initial sales presentations—I’ve learned that suppliers who excel at closing deals but falter during ongoing support create long-term headaches that no amount of initial savings can justify. Even the highest-quality AHD cameras occasionally require technical assistance, firmware updates, or warranty service that tests supplier commitment.

Technical support accessibility varies dramatically among suppliers, with multi-timezone coverage ensuring availability during your business hours regardless of supplier location. Professional suppliers offer phone, email, and web-based support channels with documented response time commitments rather than vague “we’ll get back to you” promises.

| Support Channel | Response Time Standard | Professional Requirement |

|---|---|---|

| Phone Support | Immediate during business hours | Multi-language capability |

| Email Support | 4-8 hours maximum | Technical expertise documented |

| Web Portal | 24/7 availability | Searchable knowledge base |

| Firmware Updates | Regular security patches | Version control and rollback |

Firmware management represents a critical support function that separates professional suppliers from basic operations. Regular firmware updates address security vulnerabilities and add features, requiring suppliers to maintain secure download portals with proper version control and rollback procedures.

Documentation quality reflects supplier professionalism and directly impacts your support burden. Professional suppliers provide detailed installation guides, troubleshooting resources, and searchable online knowledge bases that enable self-service problem resolution. Established manufacturers typically maintain superior documentation standards and multi-language support resources. For ongoing technical support evaluation, professional consultation can help establish support requirements and verify supplier capabilities before commitment.

Conclusions

Selecting the right AHD camera supplier requires a systematic evaluation of technical capabilities, quality processes, production capacity, pricing transparency, and support infrastructure. The global security market’s rapid growth attracts both excellent suppliers and questionable operators seeking quick profits. Following these proven selection criteria protects your project investment and ensures reliable long-term performance. Remember that the cheapest option rarely provides the best value when total cost of ownership and reliability are considered.